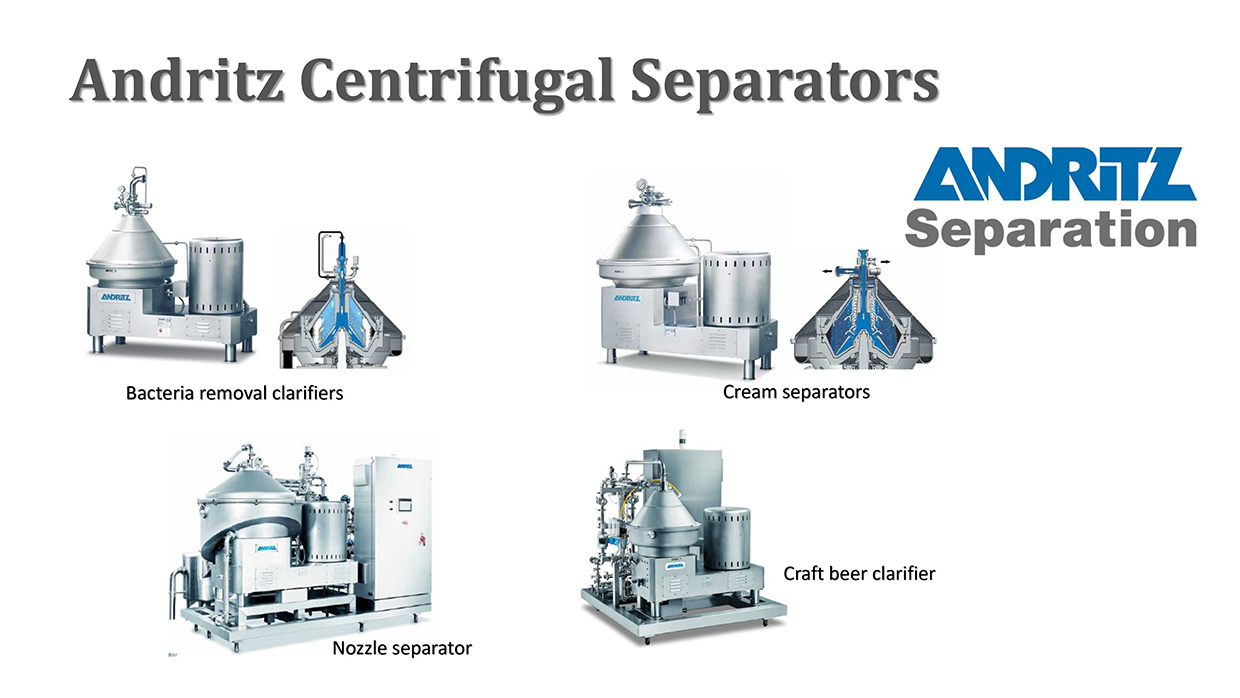

Bacteria removal clarifiers

Bacteria removal from milk and whey significantly improves the quality of final products.

For instance, in production processes where the milk

temperature does not exceed 50 °C throughout the

entire process – production of raw-milk cheese for

example – a higher product quality is obtained by using

a bacteria removal separator. Undesirable effects often

caused by bacteria, such as acid fermentation and

cheese blowing, are thus avoided.

Furthermore, a reduced shelf life of soft cheese and soft

cheese-based products may also be attributed to the

presence of bacteria. As in the previous case, bacteria

removal greatly contributes to achieving a longer life of

fresh milk and a better quality of whey-derived products,

such as protein drinks.

Used with warm milk/whey – ideally at

55-62 °C – for maximum separation efficiency, they

guarantee the highest bacteria removal rate

OPERATING PRINCIPLES

• The milk/whey is fed under pressure through an enclosed pipe.

• It then fl ows smoothly into the bowl through the feed pipe and the distributor.

• The bacteria and other solids subject to the action of the centrifugal force are forced towards the periphery of the bowl and accumulate in the solids acceleration zone before being automatically discharged at

pre-set intervals.

• The clarifi ed milk/whey rises through the disc stack and up the centripetal pump that discharges it through enclosed piping.

• The concentrate rises above the upper disc to reach the centripetal pump.

• The concentrate can either be discharged or recirculated into the bowl to further concentrate the bacteria for discharge