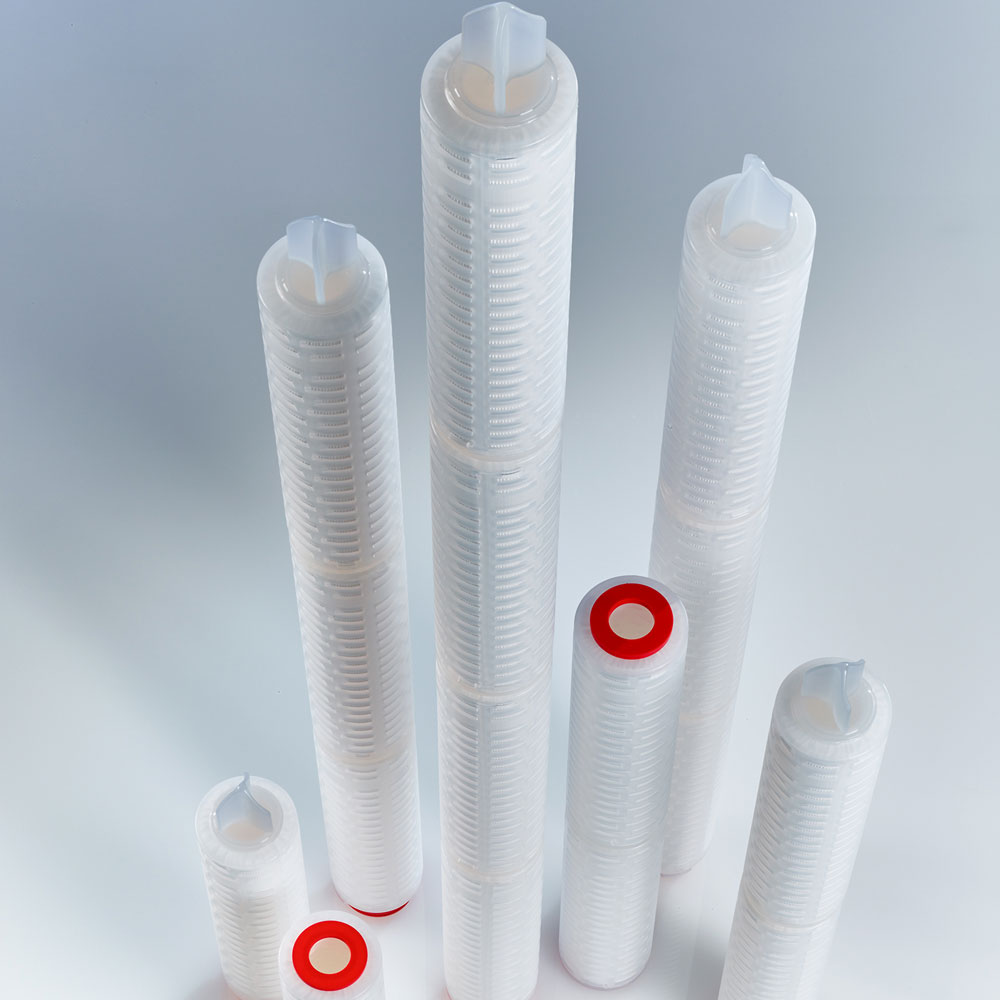

LOFPLEAT GG

The pleated borosilicate micro fiberglass filter cartridges are disposable, highly efficient and can be effectively used in a variety of industrial applications. They offer a high surface area for high flow rates.

Eaton’s LOFPLEAT GG filter cartridges are suitable for the filtration of magnetic tape coatings and as a blow-down, post filter. They are also widely used in the chemical, ink, and oil and gas industries.

FILTER MATERIAL

Fiberglass

RETENTION

90% efficiency

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- High-efficiency cartridge offering standardized pore size

- High dirt holding and flow capability

- Reduced labor costs due to less change-outs

- Fixed pore structure prevents dirt unloading even at maximum differential pressure

SPECIFICATIONS

| FILTER MATERIAL | Fiberglass |

|---|---|

| RETENTION RATING | 0.45, 1, 3, 10 (µm) |

| RETENTION EFFICIENCY | 90% |

| LENGTHS (NOMINAL) | 10“, 20“, 30“, 40“ |

| ADAPTER CODES | DOE, 1, 2, 3, 4, 10, 20, 28 |

| INNER CORE | Polypropylene |

| END CAPS | Polypropylene |

| CAGES | Polypropylene |

| MAX. OPERATING TEMPERATURE | 176 °F (80 °C) |

| MAX. PRESSURE DIFFERENCE IN FLOW DIRECTION | 58 psid at 70 °F (4.0 bar at 21 °C) |

Resources

Brochures

- (PDF 964 KB, 5/31/2019)

- (PDF 952 KB, 5/31/2019)

- (PDF 967 KB, 5/31/2019)

- (PDF 1 MB, 5/31/2019)

Technical data sheets

- (PDF 264 KB, 5/2/2019)

- (PDF 264 KB, 5/2/2019)

- (PDF 769 KB, 5/2/2019)

- (PDF 236 KB, 5/2/2019)