VACUUM WATER DEAERATION

The Vacuum Water Degassing (VWD) deaerates water down to a residual oxygen concentration below 10 ppb. Optionally the water can be cooled down, filtered or sterilized with ultraviolet light. The function of the unit can be monitored and documented by an in-line oxygen analyzer at the outlet of the unit.

The process is employed in the brewing, beverage, food and chemical-pharmaceutical industries, wherever water with lowest oxygen content is required to assure high product quality and stability. The system is characterized by high operational reliability, low CO2 and energy consumption.

ADVANTAGES AND FUNCTIONS

- Vacuum water degassing by stripping with CO2

- Very low residual oxygen values < 10 ppb

- Low CO2 consumption

- Low energy consumption

- Optional In-line oxygen analyzer, filtration or carbonization

- Hygienic design, full CIP capability

- Easy operation, low maintenance effort, long service life

- Fully automatic operation with standard PLC and touch panel

- Optional integration in process control system and remote maintenance

- Individually dimensioned and designed for each specific application

- Equipment and components according to customer specification

- Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

The water is distributed homogeneously to the structured packing at the top of the column. The CO2 is fed in at the bottom of the column. The water slowly flows downwards through the structured packing in counter current flow to the CO2.

A long and intensive contact between water and stripping gas is ensured by the high-performance structured packing. CO2 is dissolved in the water up to a level of 0.2 g/l and at the same time suppresses the oxygen. The operation of the column under vacuum, with a pressure about 80 mbar, reduces the partial pressure of gas. Low oxygen values and CO2-consumption are reached. Optionally, nitrogen can be used as stripping gas. The deaerated water is pumped out of the bottom of the column with a frequency-controlled pump. Optionally the water can be cooled down in a plate heat exchanger by glycol or ammonia.

Sensors for oxygen, level, flow and temperature monitor the proper functioning of the system.

The unit can be controlled by a local PLC with a touch panel or by a process control system.

Designed for high hygienic standards, all common cleaning agents in the beverage and chemical-pharmaceutical industry can be used for CIP cleaning.

TECHNICAL SPECIFICATION

| Capacity | 25 to 1,000 hl/h / 2.5 to 100 m3/h |

| Residual oxygen content | < 10 ppb / 0.01 ppm |

| CO2 consumption | 0.3 g/l |

| CO2 supply | min. 6 barg / ≥99.98% purity |

| Cooling media | glycol or ammonia |

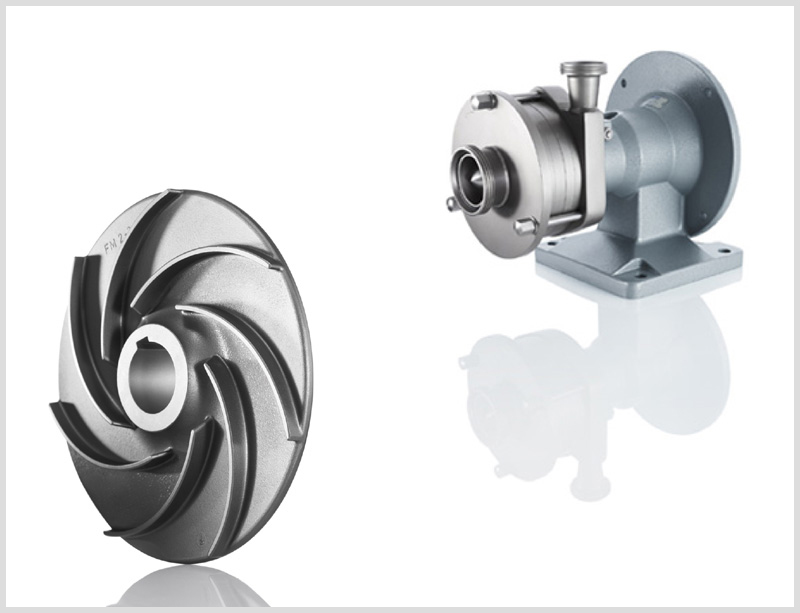

FRISTAM_FM_de.pdf | 1851.27 KB

FRISTAM_FM_de.pdf | 1851.27 KB