BECO MEMBRAN PS Pure

BECO MEMBRAN PS Pure

BECO MEMBRAN PS Pure filter cartridges made of polyethersulfone are especially designed for reliable removal of spoilage microorganisms and meet extended service life requirements of beverages, liquid food, cosmetics, fine chemical and final process water filtration.

FILTER MATERIAL

Polyethersulfone

RETENTION

Absolute (LRV-Values)

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- The asymmetric polyethersulfone membrane provides high microbiological retention and can be integrity tested

- The high filter area and asymmetric membrane structure of polyethersulfone offers exceptionally high flow rates and outstanding service life

- The special design allows for 72.5 psi (5 bar) differential pressure in the direction of flow and 29 psi (2 bar) differential pressure in reverse to support a long service life

- The high thermal stability allows more than 100 steam sterilization cycles

- Wide broad chemical compatibility from pH 1 - 14

- The large range of retention ratings from 0.2 - 1.0 µm, 3 different adapter codes and lengths from 10" - 40" offers great flexibility

- Eaton can suggest the most economical configuration of pre and final filter

| ARTICLE NUMBER | PSP02, PSP04, PSP06, PSP10 |

|---|---|

| FILTER MATERIAL | Polyethersulfone |

| RETENTION RATING (ΜM) | 0.2, 0.45, 0.65, 1 |

| RETENTION | Absolute |

| LENGTHS | 10”, 20”, 30”, 40” |

| ADAPTER CODES | 0, 2, 7 |

| CAGES | Yes |

| STRUCTURE | Pleated |

| PRESSURE HOLD TEST TEST PRESSURE IN PSIG AND DIFFUSION RATE PER 10″ | PSP02 PSP04 PSP06 PSP10 |

| BACKWASHABILITY | Limited 29 psid (2.0 bar) at 68 °F (20 °C) |

| CHEMICAL RESISTANCE | pH 1 – 14 |

| MAX. OPERATING TEMPERATURE | 176 °F (80 °C) |

| MAX. DIFFERENTIAL PRESSURE IN FLOW DIRECTION | 72.5 psid (5.0 bar) at 68°F (20 °C) 4.4 psid (0.3 bar) at 250 °F (121 °C) |

| STEAM CYCLES | ≥ 100 at 221 °F (105 °C) in 30 minutes |

Application notes

- (PDF 470 KB, 5/2/2019)

- (PDF 79 KB, 5/2/2019)

- (PDF 244 KB, 5/2/2019)

- (PDF 409 KB, 5/2/2019)

- (PDF 312 KB, 5/2/2019)

- (PDF 249 KB, 5/2/2019)

- (PDF 158 KB, 5/2/2019)

- (PDF 188 KB, 5/2/2019)

- (PDF 318 KB, 5/2/2019)

Brochures

- (PDF 850 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 856 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 830 KB, 10/18/2019)

- (PDF 850 KB, 10/18/2019)

- (PDF 926 KB, 10/18/2019)

- (PDF 852 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 859 KB, 10/18/2019)

- (PDF 914 KB, 10/18/2019)

Success stories

- BECO PROTECT CS, BECO MEMBRAN PS Pure(PDF 233 KB, 5/7/2020)

Technical data sheets

- (PDF 425 KB, 5/2/2019)

- (PDF 793 KB, 5/25/2020)

- (PDF 361 KB, 5/2/2019)

- (PDF 370 KB, 5/2/2019)

- (PDF 360 KB, 5/2/2019)

- (PDF 360 KB, 5/2/2019)

- (PDF 241 KB, 5/2/2019)

- (PDF 429 KB, 5/2/2019)

© 2019 NH-TECH.CO.TH All rights reserved.

BECO MEMBRAN PS Beer

BECO MEMBRAN PS Beer

Eaton’s BECO MEMBRAN PS Beer membrane filter cartridges are designed specifically for beer filtration.

BECO MEMBRAN PS Beer filter cartridges are designed for reliable removal of spoilage microorganisms and extended shelf life. Eaton will work with you to help ensure you produce a beer that is stable over time.

FILTER MATERIAL

Polyethersulfone

RETENTION

Absolute (LRV-Values)

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- The asymmetric polyethersulfone membrane provides high microbiological retention and can be integrity tested

- The high filter area and asymmetric membrane structure of polyethersulfone offers exceptionally high flow rates and outstanding service life

- The special design allows for 72.5 psi (5 bar) differential pressure in the direction of flow and 29 psi (2 bar) differential pressure in reverse to support a long service life

- The high thermal stability allows more than 100 steam sterilization cycles

- Broad chemical compatibility from pH 1 - 14

- Eaton can suggest the most economical configuration of pre and final filter

| ARTICLE NUMBER | PSB04, PSB06 |

|---|---|

| FILTER MATERIAL | Polyethersulfone |

| RETENTION RATING (ΜM) | 0.45, 0.65 |

| RETENTION | Absolute |

| LENGTHS | 30”, 40” |

| ADAPTER CODES | 2, 7 |

| CAGES | Yes |

| STRUCTURE | Pleated |

| PRESSURE HOLD TEST TEST PRESSURE IN PSIG AND DIFFUSION RATE PER 10″ | PSB04 PSB06 |

| BACKWASHABILITY | Limited 29 psid (2.0 bar) at 68 °F (20 °C) |

| CHEMICAL RESISTANCE | pH 1 – 14 |

| MAX. OPERATING TEMPERATURE | 176 °F (80 °C) |

| MAX. DIFFERENTIAL PRESSURE IN FLOW DIRECTION | 72.5 psid (5.0 bar) at 68°F (20 °C) 4.4 psid (0.3 bar) at 250 °F (121 °C) |

| STEAM CYCLES | ≥ 100 at 221 °F (105 °C) in 30 minutes |

Application notes

- (PDF 470 KB, 5/2/2019)

- (PDF 244 KB, 5/2/2019)

- (PDF 243 KB, 5/2/2019)

- (PDF 270 KB, 5/2/2019)

- (PDF 310 KB, 5/2/2019)

- (PDF 263 KB, 5/2/2019)

- (PDF 165 KB, 5/2/2019)

- (PDF 188 KB, 5/2/2019)

- (PDF 316 KB, 5/2/2019)

Brochures

- (PDF 850 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 856 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 830 KB, 10/18/2019)

- (PDF 850 KB, 10/18/2019)

- (PDF 926 KB, 10/18/2019)

- (PDF 1 MB, 4/1/2020)

- (PDF 1 MB, 4/1/2020)

- (PDF 1 MB, 4/1/2020)

- (PDF 1 MB, 4/1/2020)

Technical data sheets

- (PDF 490 KB, 5/2/2019)

- (PDF 229 KB, 5/2/2019)

- (PDF 381 KB, 5/2/2019)

- (PDF 370 KB, 5/2/2019)

- (PDF 371 KB, 5/2/2019)

- (PDF 305 KB, 5/2/2019)

- (PDF 434 KB, 5/2/2019)

- (PDF 370 KB, 5/2/2019)

© 2019 NH-TECH.CO.TH All rights reserved.

BECO MEMBRAN PS Aqua

BECO MEMBRAN PS Aqua

BECO MEMBRAN PS Aqua membrane filter cartridges are designed specifically for water filtration. The PES membrane provides high flow rates and extended service life for water final filtration in food and beverage applications.

FILTER MATERIAL

Polyethersulfone

RETENTION

Absolute (LRV-Values)

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- The high filter area and asymmetric membrane structure of polyethersulfone offers exceptionally high flow rates and outstanding service life

- The special design allows for 72.5 psi (5 bar) differential pressure in the direction of flow and 29 psi (2 bar) differential pressure in reverse to support a long service life

- The high thermal stability allows for more than 100 steam sterilization cycles

- Broad chemical compatibility from pH 1 - 14

| ARTICLE NUMBER | PSA02 |

|---|---|

| FILTER MATERIAL | Polyethersulfone |

| RETENTION RATING (ΜM) | 0.2 |

| RETENTION | Absolute |

| LENGTHS | 20”, 30”, 40” |

| ADAPTER CODES | 2, 7 |

| CAGES | Yes |

| STRUCTURE | Pleated |

| PRESSURE HOLD TEST TEST PRESSURE IN PSIG AND DIFFUSION RATE PER 10″ | PSA02 |

| BACKWASHABILITY | Limited 29 psid (2.0 bar) at 68 °F (20 °C) |

| CHEMICAL RESISTANCE | pH 1 – 14 |

| MAX. OPERATING TEMPERATURE | 176 °F (80 °C) |

| MAX. DIFFERENTIAL PRESSURE IN FLOW DIRECTION | 72.5 psid (5.0 bar) at 68°F (20 °C) 4.4 psid (0.3 bar) at 250 °F (121 °C) |

| STEAM CYCLES | ≥ 100 at 221 °F (105 °C) in 30 minutes |

Brochures

- (PDF 850 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 856 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 830 KB, 10/18/2019)

- (PDF 850 KB, 10/18/2019)

- (PDF 926 KB, 10/18/2019)

- (PDF 852 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 859 KB, 10/18/2019)

- (PDF 914 KB, 10/18/2019)

Technical data sheets

- (PDF 390 KB, 5/2/2019)

- (PDF 172 KB, 5/2/2019)

- (PDF 351 KB, 5/2/2019)

- (PDF 363 KB, 5/2/2019)

- (PDF 347 KB, 5/2/2019)

- (PDF 352 KB, 5/2/2019)

- (PDF 233 KB, 5/2/2019)

- (PDF 415 KB, 5/2/2019)

© 2019 NH-TECH.CO.TH All rights reserved.

BECO MEMBRAN PFplus

BECO MEMBRAN PFplus

Eaton offers high-quality beverage filtration products designed and built to the latest, most exacting quality standards. BECO MEMBRAN PFplus pleated membrane filter cartridges are designed for the removal of spoilage microorganisms and provide a long service life thanks to excellent mechanical and thermal stability. BECO MEMBRAN PFplus filter cartridges can be integrity tested.

FILTER MATERIAL

Polyvinylidene fluoride (PVDF)

RETENTION

Absolute (LRV-Values)

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- Long service life through larger filter area and excellent mechanical stability

- High microbiological retention due to uniform pore sizes

- Very good resistance to sterilization media and cleaning solutions

- The filter can be sterilized many times with steam or hot water

- Used filter cartridges can be stored dry; the membrane retains its wettability and elasticity during storage

| ARTICLE NUMBER | KVBB, KVBY, (KVBA) |

|---|---|

| FILTER MATERIAL | Polyvinylidene fluoride (PVDF) |

| RETENTION RATING (ΜM) | 0.45, 0.65 |

| RETENTION | Absolute |

| LENGTHS | 30” |

| ADAPTER CODES | 7 |

| CAGES | Yes |

| STRUCTURE | Pleated |

| PRESSURE HOLD TEST TEST PRESSURE IN PSIG AND DIFFUSION RATE PER 10″ | KVBB = 0.45 μm KVBY = 0.65 μm |

| BACKWASHABILITY | Limited up to 50 psid (3.5 bar) at 77 °F (25 °C) |

| CHEMICAL RESISTANCE | pH 1 – 12 |

| MAX. OPERATING TEMPERATURE | 176 °F (80 °C) |

| MAX. DIFFERENTIAL PRESSURE IN FLOW DIRECTION | 72.5 psid (5.0 bar) at 68°F (20 °C) 4.4 psid (0.3 bar) at 250 °F (121 °C) |

| STEAM CYCLES | ≥ 100 At 230 °F (110 °C) in 30 minutes |

Application notes

- (PDF 472 KB, 5/2/2019)

- (PDF 79 KB, 5/2/2019)

- (PDF 242 KB, 5/2/2019)

- (PDF 258 KB, 5/2/2019)

- (PDF 299 KB, 5/2/2019)

- (PDF 262 KB, 5/2/2019)

- (PDF 160 KB, 5/2/2019)

- (PDF 188 KB, 5/2/2019)

- (PDF 317 KB, 5/2/2019)

Brochures

- (PDF 850 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 856 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 830 KB, 10/18/2019)

- (PDF 850 KB, 10/18/2019)

- (PDF 926 KB, 10/18/2019)

Success stories

- Hubert Sekt achieved microbiological stability of sparkling wines and other wines with high cost efficiency.(PDF 308 KB, 5/10/2019)

Technical data sheets

- (PDF 582 KB, 5/2/2019)

- (PDF 432 KB, 5/2/2019)

- (PDF 500 KB, 5/2/2019)

- (PDF 435 KB, 5/2/2019)

- (PDF 424 KB, 5/2/2019)

- (PDF 419 KB, 5/2/2019)

- (PDF 421 KB, 5/2/2019)

- (PDF 523 KB, 5/2/2019)

© 2019 NH-TECH.CO.TH All rights reserved.

BECO MEMBRAN H Air Mini

BECO MEMBRAN H Air Mini

BECO MEMBRAN H Air Mini filter cartridges with 0.2 µm hydrophobic single layer membranes made of Polytetrafluorethylene (PTFE) are ideal for sterile air filtration and gas filtration in the food and beverage industry. The filter cartridges remove contaminants in small volumes in applications such as sterilizing fermenter supply air, tank ventilation, or cooling down storage tanks after steam sterilization. The PTFE membrane filter cartridges are available in 1″ and 5″ lengths.

FILTER MATERIAL

Teflon (PTFE)

RETENTION

Absolute (LRV-Values)

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- Long-term steam-resistance at 273 °F (134 °C)

- Validated bacteria retention capacity

- Very low inherent membrane resistance provides high throughput

ARTICLE NUMBER | PTM02 |

|---|---|

| FILTER MATERIAL | Teflon (PTFE) |

| RETENTION RATING | 0.2 (µm) |

| RETENTION | Absolute |

| LENGTHS | 1”, 5” |

| ADAPTER CODES | 1, 4, 7 |

| CAGES | Yes |

| STRUCTURE | Pleated |

| PRESSURE HOLD TEST | PTM02 |

| TEST PRESSURE IN PSIG AND DIFFUSION RATE PER 10″ | Bubble point test at 20 °C ≥ 1000 mbar in 60% isopropanol |

| BACKWASHABILITY | Yes |

| CHEMICAL RESISTANCE | pH 1 – 14 |

| MAX. OPERATING TEMPERATURE | 80 °C |

| MAX. DIFFERENTIAL PRESSURE IN FLOW DIRECTION | 5.0 bar at 20°C 0.5 bar at 134 °C |

| STEAM CYCLES | 50 at 134 °C in 20 minutes |

Brochures

- (PDF 850 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 856 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 830 KB, 10/18/2019)

- (PDF 850 KB, 10/18/2019)

- (PDF 926 KB, 10/18/2019)

- (PDF 852 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 859 KB, 10/18/2019)

- (PDF 914 KB, 10/18/2019)

Technical data sheets

- (PDF 496 KB, 5/2/2019)

- (PDF 357 KB, 5/2/2019)

- (PDF 181 KB, 5/2/2019)

- (PDF 204 KB, 5/2/2019)

- (PDF 364 KB, 5/2/2019)

- (PDF 238 KB, 5/2/2019)

- (PDF 423 KB, 5/2/2019)

- (PDF 346 KB, 5/2/2019)

© 2019 NH-TECH.CO.TH All rights reserved.

BECO MEMBRAN H Air

BECO MEMBRAN H Air

Pleated PTFE membrane filter cartridges for sterile filtration of gases and air.

BECO MEMBRAN H Air filter cartridges with 0.2 µm hydrophobic single layer membranes made of Polytetrafluorethylene (PTFE) are ideal for sterile air filtration and gas filtration in the food and beverage industry. The filter cartridges remove contaminants in large volumes in applications such as sterilizing fermenter supply air, tank ventilation, or cooling down storage tanks after steam sterilization. The PTFE membrane filter cartridges are available in 10″, 20″, and 30″ lengths.

FILTER MATERIAL

Teflon (PTFE)

RETENTION

Absolute (LRV-Values)

MAX. OPERATING TEMPERATURE

176 °F (80 °C)

Core features

- Long-term steam-resistance at 273 °F (134 °C)

- Validated bacteria retention capacity

- High throughput due to very low inherent membrane resistance

| ARTICLE NUMBER | PTC02 |

|---|---|

| FILTER MATERIAL | Teflon (PTFE) |

| RETENTION RATING (ΜM) | 0.2 |

| RETENTION | Absolute |

| LENGTHS | 10”, 20”, 30” |

| ADAPTER CODES | 7 |

| CAGES | Yes |

| STRUCTURE | Pleated |

| PRESSURE HOLD TEST TEST PRESSURE IN PSIG AND DIFFUSION RATE PER 10″ | PTC02 |

| BACKWASHABILITY | Yes (20 °C) |

| CHEMICAL RESISTANCE | pH 1 – 14 |

| MAX. OPERATING TEMPERATURE | 176 °F (80 °C) |

| MAX. DIFFERENTIAL PRESSURE IN FLOW DIRECTION | 72.5 psid (5.0 bar) at 68°F (20 °C) 7.25 psid (0.5 bar) at 273 °F (134 °C) |

| STEAM CYCLES | ≥ 150 at 273 °F (134 °C) in 20 minutes |

Brochures

- (PDF 850 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 856 KB, 10/18/2019)

- (PDF 854 KB, 10/18/2019)

- (PDF 830 KB, 10/18/2019)

- (PDF 850 KB, 10/18/2019)

- (PDF 926 KB, 10/18/2019)

- (PDF 852 KB, 10/18/2019)

- (PDF 844 KB, 10/18/2019)

- (PDF 859 KB, 10/18/2019)

- (PDF 914 KB, 10/18/2019)

Technical data sheets

- (PDF 430 KB, 5/2/2019)

- (PDF 356 KB, 5/2/2019)

- (PDF 355 KB, 5/2/2019)

- (PDF 194 KB, 5/2/2019)

- (PDF 184 KB, 5/2/2019)

- (PDF 229 KB, 5/2/2019)

- (PDF 427 KB, 5/2/2019)

- (PDF 342 KB, 5/2/2019)

© 2019 NH-TECH.CO.TH All rights reserved.

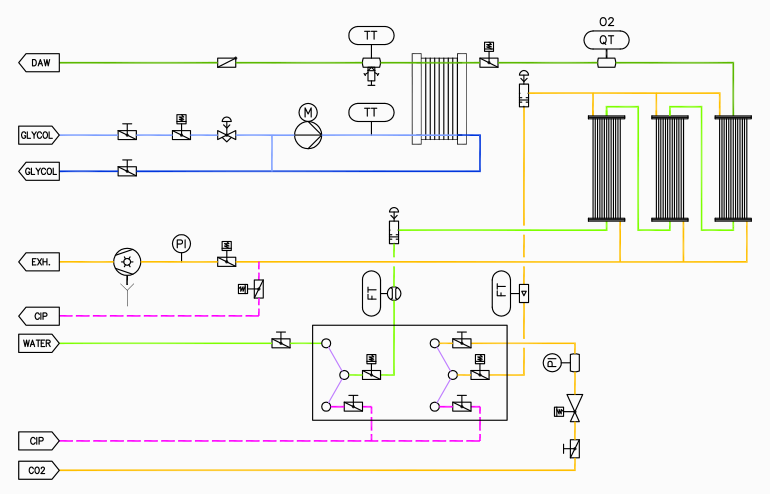

MEMBRANE WATER DEAERATION MWD

MEMBRANE WATER DEAERATION

The Membrane Water Deaeration (MWD) deaerates water down to a residual oxygen concentration below 10 ppb, using highly efficient hollow fibre membrane modules. Optionally, the water can be cooled down, filtered or sterilized with ultraviolet light. The function of the unit can be monitored and documented by an in-line oxygen analyzer at the outlet of the unit.

The process is used in the brewing, beverage, food and chemical-pharmaceutical industries, wherever water with very low oxygen content is required to ensure high product quality and stability. The system is characterized by high operational reliability as well as low CO2 and energy consumption.

ADVANTAGES AND FUNCTIONS

- Deaeration of water with highly efficient hollow fibre membranes

- Very low residual oxygen values < 10 ppb

- Low CO2 consumption

- Low energy consumption

- Optional in-line oxygen analyzer, filtration or carbonization

- Hygienic design, full CIP capability

- Easy operation, low maintenance effort

- Fully automatic operation with standard PLC and touch panel

- Optional integration in process control system and remote maintenance

- Individually dimensioned and designed for each specific application

- Equipment and components according to customer specification

- Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

Inside the modules, water flows on the outside around the hydrophobic hollow fibres; inside, in counter- current flow, stripping gas flows. The hollow fibres create an extremely large contact surface between the stripping gas and the deaerated water and let gas through, but no water. The generated vacuum on the gas side of approx. 65 mbar sucks the gas mixture from the modules. Because of the high differential partial pressure caused by the vacuum and the strip- ping gas, the oxygen molecules diffuse from the water into the vacuum. Nitrogen or CO2 can be used as stripping gas.

After passing the membrane modules, the water can optionally be cooled down in a plate heat exchanger.

Sensors for oxygen, flow and temperature monitor the proper functioning of the system. By arranging the modules parallel and in series, almost any capacity and residual oxygen value can be achieved.

The unit can be controlled by a local PLC with a touch panel or by a process control system. Designed for high hygienic standards, all common cleaning agents in the beverage and chemical- pharmaceutical industry can be used for CIP cleaning.

TECHNICAL SPECIFICATION

| Capacity | 5 to 1,000 hl/h / 0.5 to 100 m3/h |

| Residual oxygen content | < 10 ppb / 0.01 ppm |

| CO2 consumption | 0.6 g/l |

| CO2 supply | min. 6 barg / ≥99.98% purity |

| Cooling media | glycol or ammonia |

© 2019 NH-TECH.CO.TH All rights reserved.

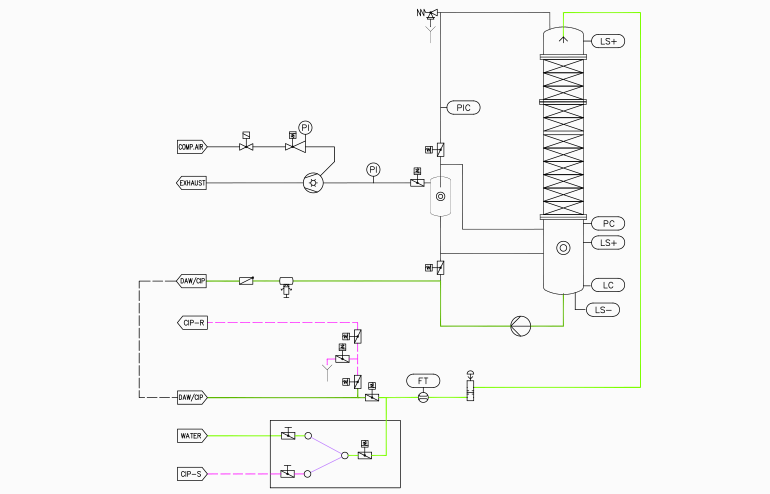

HOT WATER DEAERATION HWD

HOT WATER DEAERATION

The Hot Water Deaeration (HWD) deaerates water down to a residual oxygen concentration below 10 ppb. At the same time the water is pasteurized. Optionally it can be cooled down, filtered or pre-carbonised. The function of the unit can be monitored and documented by an in-line oxygen analyzer at the outlet of the unit.

The process is employed in the brewing, beverage, food and chemical-pharmaceutical industries, wherever water with lowest oxygen content is required to assure high product quality and stability. The system is characterized by high operational reliability, high heat recuperation up to 95% and low consumption. Microbiological safety is ensured by the simultaneous pasteurization of the water.

ADVANTAGES AND FUNCTIONS

- Hot water deaeration by stripping with CO2

- Very low residual oxygen values < 10 ppb

- Simultaneous pasteurization / sterilization of the water

- High heat recuperation up to 95%

- Optional In-line oxygen analyzer, filtration or carbonization

- Hygienic design, full CIP capability

- Easy operation, low maintenance effort, long service life

- Fully automatic operation with standard PLC and touch panel

- Optional integration in process control system and remote maintenance

- Individually dimensioned and designed for each specific application

- Equipment and components according to customer specification

- Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

The water is heated up to 74 °C in a 3-zone plate heat exchanger by the already deaerated water coming from the stripping column and by low pressure steam. The water is distributed homogeneously to the structured packing at the top of the column. The water slowly flows downwards through the structured packing in counter current flow to the CO2. The CO2 is fed in at the bottom of the column.

A long and intensive contact between water and stripping gas is ensured by the high-performance structured packing. CO2 is dissolved in the water up to a level of 0.5 g/l and at the same time suppresses the oxygen. Optionally, nitrogen can be used as stripping gas. The deaerated water is pumped from the bottom of the column through the plate heat exchanger, where it is cooled by the incoming water. Finally, the water is cooled to 2 °C in the plate heat exchanger by glycol or ammonia.

Sensors for oxygen, level, flow and temperature monitor the proper functioning of the system.

The unit can be controlled by a local PLC with a touch panel or by a process control system.

Designed for high hygienic standards, all common cleaning agents in the beverage and chemical-pharmaceutical industry can be used for CIP cleaning.

TECHNICAL SPECIFICATION

| Capacity | 25 to 1,000 hl/h / 2.5 to 100 m3/h |

| Residual oxygen content | < 10 ppb / 0.01 ppm |

| Heat recovery | up to 95 % |

| CO2 consumption | 0.8 g/l |

| CO2 supply | min. 6 barg / = 99.98 % purity |

| Heating media | steam or hot water |

| Cooling media | glycol or ammonia |

© 2019 NH-TECH.CO.TH All rights reserved.

HIGH VACUUM WATER DEAERATION V2WD

HIGH VACUUM WATER DEAERATION

The High Vacuum Water Deaeration (V2WD) is a new development by corosys GmbH. It deaerates water down to a residual oxygen concentration below 10 ppb without use of stripping gas. Optionally the water can be cooled down, filtered or sterilized with ultraviolet light. The function of the unit can be monitored and documented by an in-line oxygen analyzer at the outlet of the unit.

The process is employed in the brewing, beverage, food and chemical-pharmaceutical industries and the power industry, wherever water with lowest oxygen content is required to assure high product quality and stability and to avoid corrosion.

The system is characterized by high operational reliability and low energy consumption.

ADVANTAGES AND FUNCTIONS

- Water deaeration with a two-step vacuum process without stripping gas, CO2 or N2

- Zero Emission of greenhouse gases

- Very low residual oxygen values < 10 ppb

- Low energy consumption

- Optional In-line oxygen analyzer, filtration or carbonization

- Hygienic design, full CIP capability

- Easy operation, low maintenance effort, long service life

- Fully automatic operation with standard PLC and touch panel

- Optional integration in process control system and remote maintenance

- Individually dimensioned and designed for each specific application

- Equipment and components according to customer specification

- Compact tubular-frame system (skid mounted)

TECHNICAL DESCRIPTION

The water is distributed homogeneously to the structured packing at the top of the column. It slowly flows downwards through the structured packing. An excellent distribution of the water in the column is ensured by the high-performance structured packing. The resulting enlargement of the contact surface of water causes an optimal removal of oxygen. Due to the combination of two degassing steps operated at different pressures, lowest oxygen values are reached.

No stripping gas is used and zero greenhouse gas is emitted. The deaerated water is pumped out of the bottom of the column with a frequency-controlled pump. Optionally the water can be cooled down in a plate heat exchanger by glycol or ammonia.

Sensors for oxygen, level, flow and temperature monitor the proper functioning of the system.

The unit can be controlled by a local PLC with a touch panel or by a process control system. Designed for high hygienic standards, all common cleaning agents in the beverage and chemical-pharmaceutical industry can be used for CIP cleaning.

TECHNICAL SPECIFICATION

| Capacity | 25 bis 1000 hl/h / 2,5 bis 100 m3/h |

| Residual oxygen conten | < 10 ppb / 0.01 ppm |

| CO2 consumption | 0,00 g/l |

| Cooling media | glycol or ammonia |