Solid bowl separators, a cost-effective solution for smaller-scale milk processing

The same design criteria adopted for the large, selfcleaning separators are used for our solid bowl separators,

making them extremely reliable and efficient. Ease of

use and maintenance, together with sturdy construction

guarantee peace of mind for our customers in terms

of ownership costs and long, trouble-free life of the

equipment.

FEATURES

• Large solids space to allow for extended running times

• Built-in, manual back-pressure control and milk fat standardization valve

• High-grade finish on all surfaces (wet and dry parts) for easy cleaning and sanitization

TECHNICAL INFORMATION

• Feed pressure: 1 bar

• Discharge pressure of >clarified milk, skimmed milk/whey: up to 5 bar

• Product connections: DIN 11851 – SMS – CLAMP

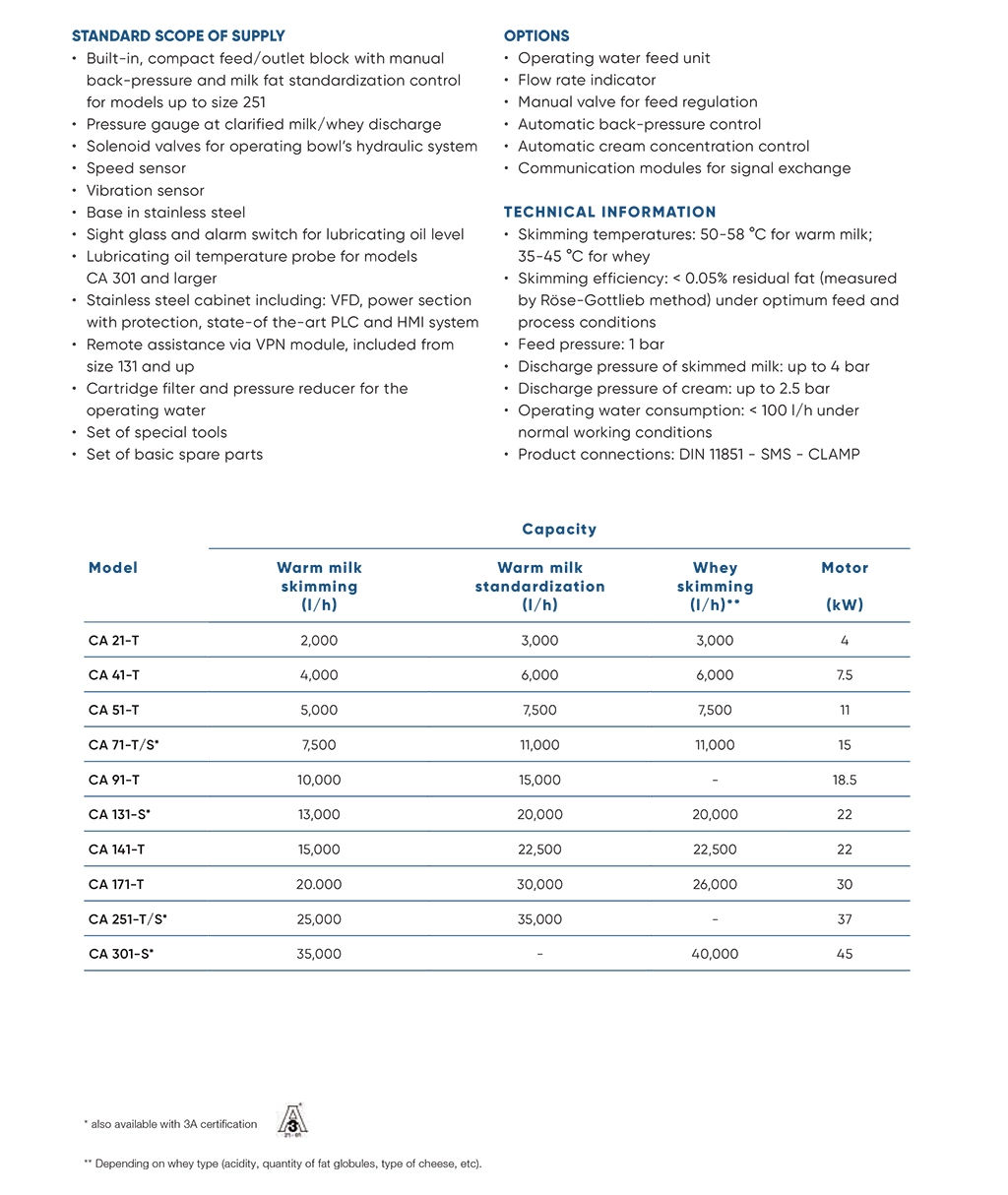

STANDARD SCOPE OF SUPPLY

• Clarifer/cream separator

• Manual back-pressure control

• Manual milk fat standardization control for cream separators

• Stainless steel-clad base frame, provided with supporting legs and vibration dampers

• Pressure gauge at clarified/skimmed milk/whey discharge

• Tachometer for gear-driven models

FEATURES

• Large solids space to allow for extended running times

• Built-in, manual back-pressure control and milk fat standardization valve

• High-grade finish on all surfaces (wet and dry parts) for easy cleaning and sanitization

TECHNICAL INFORMATION

• Feed pressure: 1 bar

• Discharge pressure of >clarified milk, skimmed milk/whey: up to 5 bar

• Product connections: DIN 11851 – SMS – CLAMP

STANDARD SCOPE OF SUPPLY

• Clarifer/cream separator

• Manual back-pressure control

• Manual milk fat standardization control for cream separators

• Stainless steel-clad base frame, provided with supporting legs and vibration dampers

• Pressure gauge at clarified/skimmed milk/whey discharge

• Tachometer for gear-driven models

• Frame-mounted inductive sensor for belt drive models

• Vibration sensor

• Control panel including VFD for motor control (belt drive

models only)

• Set of special service tools

• Set of basic spare parts

OPTIONS

• Control panel for gear-driven models

• Flow rate indicator

• Manual valve for feed regulation

MAIN BENEFITS

• Easy installation and operation

• Long running time without interruptions for

cleaning

• High separation efficiency

• Reduced ownership costs

• Peace of mind for the customer