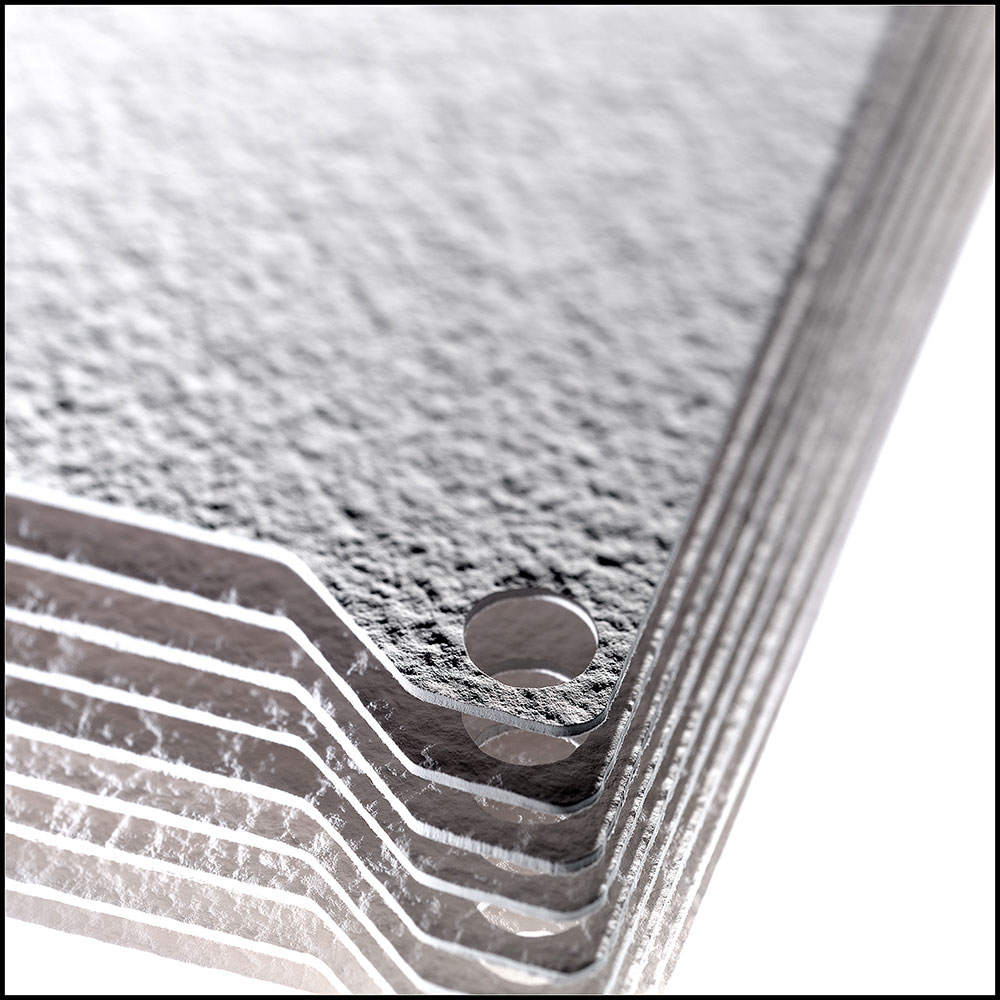

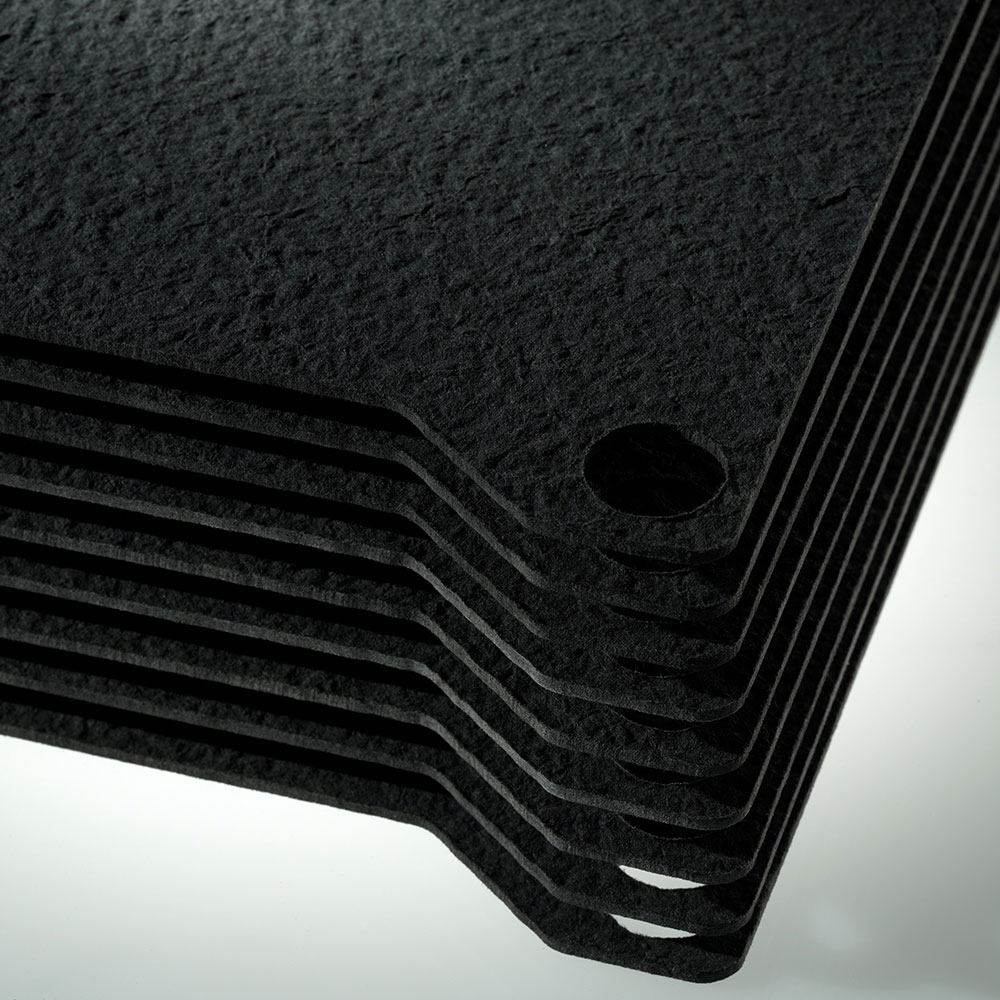

BECO CPS

BECO CPS depth filter sheets are used for clarifying filtration in the chemical, cosmetic and food industries. The filter sheets remove particles of a coarse, crystalline, amorphous or gel-like structure perfectly. An extremely wide range of filtration tasks can be performed according to given specifications, even with highly viscous liquids.

FILTER MATERIAL

Cellulose with mineral components (CP2KS / CP2KS without mineral components)

RETENTION

Coarse, clarifying and fine filtration

MAX. OPERATING TEMPERATURE

FDA, EC1935

Core features

- High dirt-holding capacity for economic filtration

- Differentiated fiber and cavity structure (internal surface area) for the widest possible range of applications and operating conditions

- The ideal combination of filtration-active and adsorptive properties ensures maximum safety

- Very pure raw materials and therefore minimum influence on filtrates

- Comprehensive quality assurance for all raw and auxiliary materials and intensive in-process controls ensure consistent quality of the finished products

Special Depth Filters

BECO CP1KS, CP2KS

- High-purity cellulose

- Low washable ions

- No mineral components

- Near complete catalyst separation at high flow rates

- Near complete catalyst recovery

These special BECO depth filter sheets were developed for highest demands in the chemical industry. By using and selecting high-purity cellulose, the content of washable ions is exceptionally low. Since these depth filters contain no mineral components, there are only traces of iron and aluminum migration. Complete separation of catalysts at high flow rates is also possible using Eaton’s BECO CPS depth filter sheets. Subsequent ashing enables virtually loss-free and nearly complete recovery of catalysts.

Coarse Filtration

BECO CP07S, CP03S, CP02S, CP01S

BECO depth filters with filter-active, mineral components for clarification of liquids with a coarser crystalline and amorphous, or gel-like particle structure and is suitable for high-viscosity liquids

Applications:

- Concentrated sugar solution

- Active earth separation

- Resin melts

- Insulation oils

- Boiled linseed oils

- Nail varnish

- Ointment base

- Syrup

- Cooking oils

- Vegetable extracts

- Gelatin broths

- Paint

- Polymer dispersions

- Filtration of Fuller's earth

Applications:

- Beer

- Wine

- Fruit juice

- Fruit wine

- Fine chemicals

- Pharmaceuticals

| Type | Article number | Nominal retention rate µm | Water throughput △ p = 14.5 psi gpm/ft2 (△ p = 100 kPa l/m2/min) |

| BECO CP07S | 27108 | 15.0 | 105.3 (4290) |

| BECO CP03S | 27123 | 20.0 | 175.2 (7140) |

| BECO CP02S | 27122 | 25.0 | 233.6 (9520) |

| BECO CP01S | 27121 | 30.0 | 306.8 (1250) |

| BECO CP2KS | 27031 | 27.0 | 239.5 (9760) |

| BECO CP1KS | 27021 | 40.0 | 555.1 (22620) |

Brochures

- (PDF 820 KB, 1/13/2020)

- (PDF 932 KB, 1/13/2020)

- (PDF 958 KB, 1/13/2020)

- (PDF 812 KB, 1/13/2020)

- (PDF 845 KB, 1/13/2020)

- (PDF 824 KB, 1/13/2020)

- (PDF 815 KB, 1/13/2020)

- (PDF 808 KB, 1/13/2020)

Material safety data sheet (MSDS)

- (PDF 69 KB, 5/2/2019)

- (PDF 68 KB, 5/2/2019)

- (PDF 66 KB, 5/2/2019)

- (PDF 68 KB, 5/2/2019)

- (PDF 69 KB, 5/2/2019)

- (PDF 65 KB, 5/2/2019)

- (PDF 69 KB, 5/2/2019)

- (PDF 76 KB, 5/2/2019)

- (PDF 68 KB, 5/2/2019)

- (PDF 68 KB, 5/2/2019)

- (PDF 66 KB, 5/2/2019)

- (PDF 67 KB, 5/2/2019)

- (PDF 68 KB, 5/2/2019)

- (PDF 65 KB, 5/2/2019)

- (PDF 68 KB, 5/2/2019)

- (PDF 76 KB, 5/2/2019)

Technical data sheets

- (PDF 658 KB, 5/2/2019)

- (PDF 379 KB, 5/2/2019)

- (PDF 387 KB, 5/2/2019)

- (PDF 514 KB, 5/2/2019)

- (PDF 382 KB, 5/2/2019)

- (PDF 384 KB, 5/2/2019)

- (PDF 366 KB, 5/2/2019)

- (PDF 532 KB, 5/2/2019)