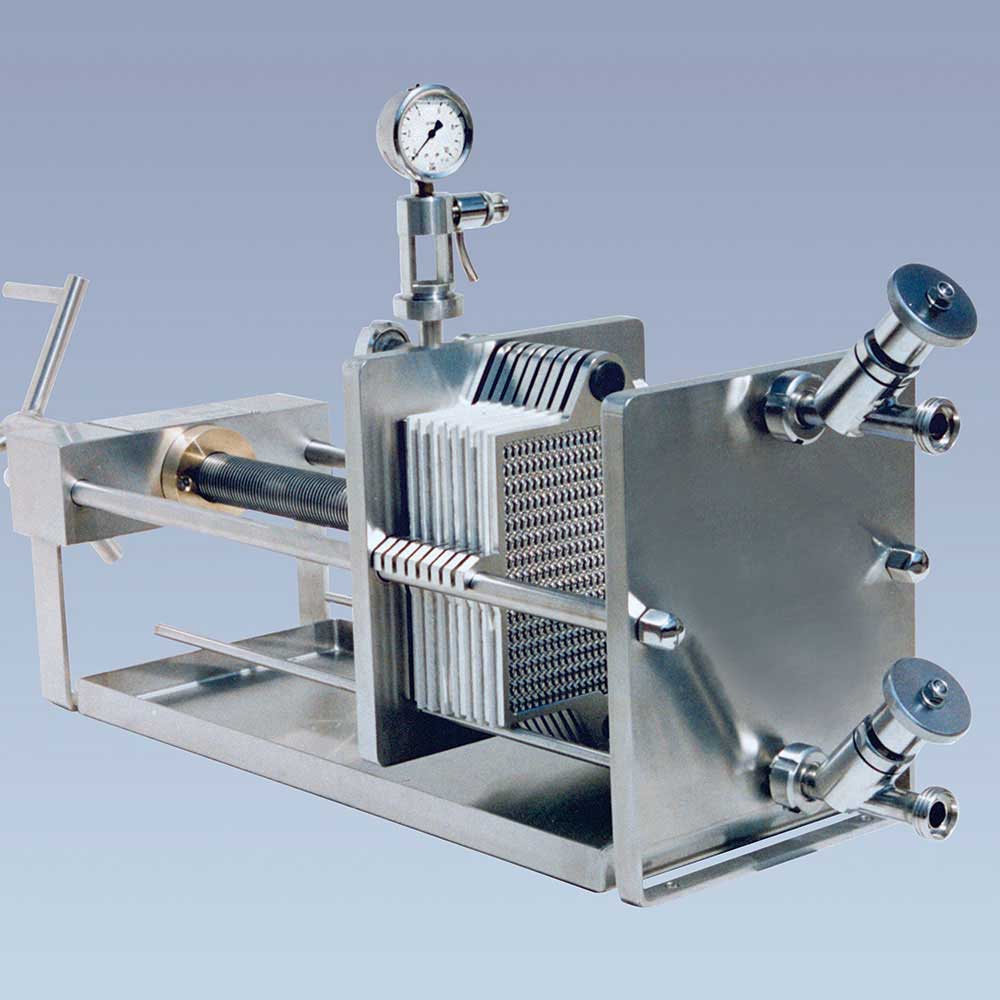

BECO INTEGRA PLATE A200 EP/OEP

Eaton’s depth filtration system for critical filtration tasks in the pharmaceutical, biotech, chemical, cosmetic, and food industries.

BECO INTEGRA PLATE A200 EP/OEP is an enclosed multi-sheet filter with external chamber. Depth filter sheets seal the product channels.

The BECO INTEGRA PLATE A200 EP version has gaskets at the external chamber that seal the entire filter package. The BECO INTEGRA PLATE A200 OEP version has a gasket-free filter package.

CLEANING

CIP/SIP

DESIGN

With External Chamber

MATERIAL

PP or PVDF, FDA listed

Core features

- CIP of filter package without depth filter sheets

- Complete drainage of filter due to unique filter plate design

- Safe operation: No drip loss due to sealed external chamber

- Easy handling and good cleanability thanks to ergonomic design of chassis, and open support grid of filter plates; cake discharge downwards into tray underneath of filter package

- High flexibility: The filter can be used as a sheet filter or as a pre-coat filter. For pre-coating/removing of high particle load, cake frames in different widths are available

Industries include:

- Pharmaceuticals

- Biotech

- Fine Chemicals

- Chemicals

- Cosmetics

- Food

- Beverages

Eaton’s BECO INTEGRA PLATE A200 EP/OEP is designed and manufactured according to the cGMP guidelines and the FDA regulations.

SPECIFICATIONS

| Operating pressure/ temperature: | max. 72.5 psi (500 kPa/5 bar) at 104 °F (40 °C) max. 29 psi (200 kPa/2 bar) at 140 °F (60 °C) |

| CIP | Max. 14.-5 psi (100 kPa/1 bar) at 185 °F (85 °C) |

| Differential pressure/ temperature: | max. 43.5 psi (300 kPa/3 bar) at 104 °F (40 °C) |

| Filter area per sheet: | 0.3 ft² (0.028 m²) |

| Product contacting parts: | Polypropylene/ Stainless steel AISI 316L |

| Other parts: | Stainless steel AISI 304 |

| Gaskets/O-rings: | Silicone, EPDM (FDA listed), Viton |

| Filter inlet: | TC 3/4″ ISO2852/ASME BPE |

| Filter outlet: | TC 3/4″ ISO2852/ASME BPE |

| External chamber: | TC 1/2″ ISO2852/ASME BPE |

FILTER PLATES/CAKE FRAMES

| Width in (mm) | Cake volume* gal (l) | Weight lb (kg) |

| Initial/ end plate | 0.91 (23) | 2.65 (1.2) |

| Filter plate | 0.91 (23) | 2.43 (1.1) |

| Cake frame | 0.79 (20) | 1.32 (0.6) |

| Cake frame | 1.18 (30) | 1.76 (0.8) |

| Cake frame | 1.57 (40) | 2.43 (1.1) |

| Cake frame | 2.36 (60) | 3.75 (1.7) |

| Type | Filter area | Cake volume* | Chassis | Filter plates/ cake frames | Depth filter sheets 6.14 x 9.04 in (156 x 229.5 mm) | approx. |

| ft² (m²) | gal (l) | qty. | qty. | ≈ lb (kg) | ||

| 200 SF with 0.91″ (23 mm) feeding elements | 7.84 (0.728) | – | 1 | 12/13 | 26 | 330 (150) |

| 200 ASF with 0.79″ (20 mm) cake frames | 9.04 (0.840) | 1.66 (6.3) | 1 | 14/15 | 30 | 322 (146) |

| 200 ASF with 1.18″ (30 mm) cake frames | 7.23 (0.672) | 2.22 (8.4) | 1 | 11/12 | 24 | 318 (144) |

| 200 ASF with 1.57″ (40 mm) cake frames | 6.03 (0.560) | 2.59 (9.8) | 1 | 9/10 | 20 | 313 (142) |

| 200 ASF with 2.36″ (60 mm) cake frames | 4.82 (0.448) | 3.25 (12.3) | 1 | 7/ 8 | 16 | 313 (142) |

Resources

Brochures

- (PDF 705 KB, 9/5/2019)

- (PDF 697 KB, 9/5/2019)

- (PDF 926 KB, 9/5/2019)

- (PDF 697 KB, 9/5/2019)

- (PDF 696 KB, 9/5/2019)

- (PDF 695 KB, 9/5/2019)

- (PDF 698 KB, 9/5/2019)

Technical data sheets

- (PDF 186 KB, 5/2/2019)

- (PDF 196 KB, 5/2/2019)

- (PDF 141 KB, 9/5/2019)