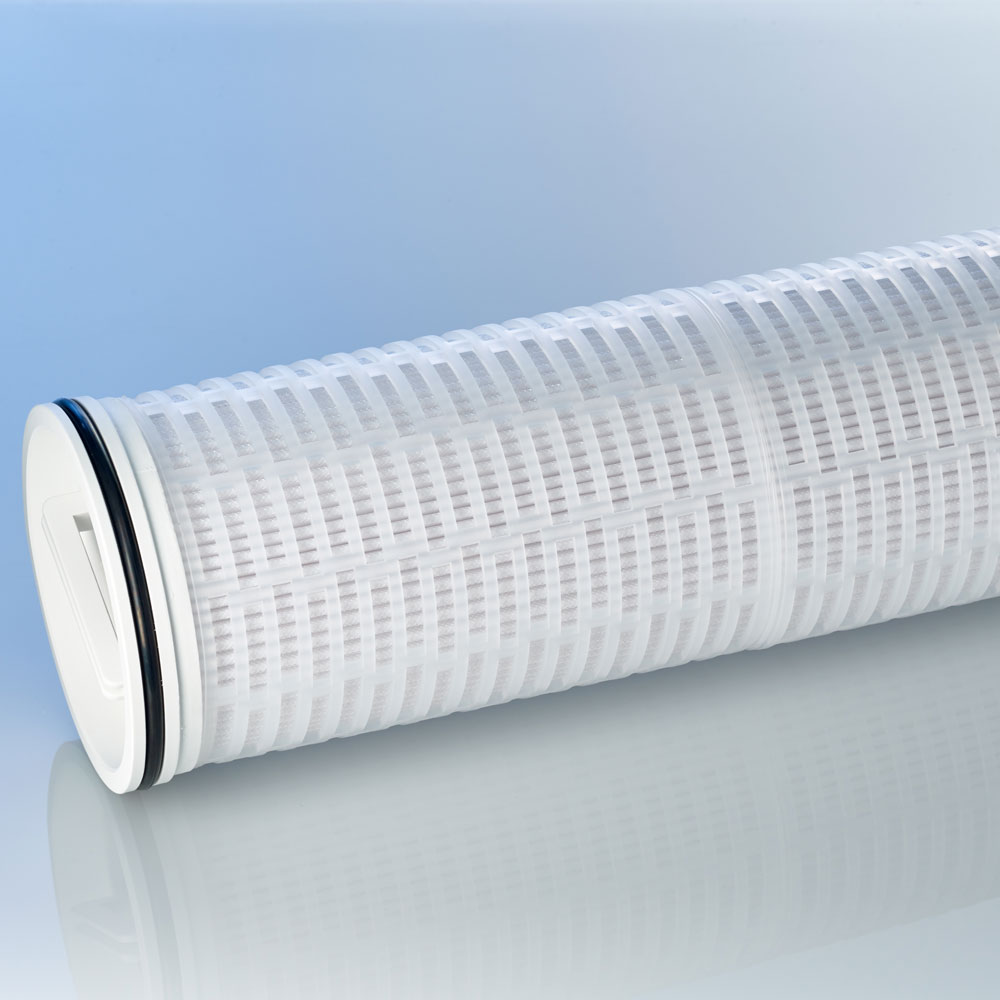

LOFPLEAT HF G

LOFPLEAT HF-G filter cartridges are designed with pleated micro fiberglass filter material construction to provide a high total surface area. A single LPHF-G filter cartridge can replace several standard cartridge elements. Change-outs are quick and easy. Unlike standard design filter cartridges, the flow is inside out. The result is higher dirt-holding capacity.

Eaton’s LOFPLEAT HF-G filter cartridges can be used in a variety of applications where high flow capacity is required including fuel oils, chemicals, petrochemicals, solvents and oil and gas.

FILTER MATERIAL

Fiberglass

RETENTION

99.9% efficiency

MAX. OPERATING TEMPERATURE

Polypropylene: 180°F (82°C); Polyacetal: 230°F (110°C)

Core features

- Higher flow capacity reduces required number of filter cartridges

- Lower initial costs with smaller filter housings

- Less labor required for change-outs

- Available with absolute rated filter material at 1 to 20 μm retention ratings

- Inside-out flow for greater dirt holding capacity

- Capable of flow rates up to 1892.5 l/min in a single 60" length

- Can be retrofitted in most competitive high-flow housings

- Thermally bonded construction

SPECIFICATIONS

| FILTER MATERIAL | Fiberglass |

|---|---|

| RETENTION RATING | 1, 2.5, 4.5, 10, 20 (µm) |

| RETENTION EFFICIENCY | 99.9% |

| LENGTHS (NOMINAL) | 20″, 40″, 60″ |

| ADAPTER CODES | – |

| INNER CORE | – |

| END CAPS | Polypropylene or polyacetal |

| CAGES | Polypropylene or polyacetal |

| MAX. OPERATING TEMPERATURE | Polypropylene: 180 °F (82 °C) Polyacetal: 230 °F (110 °C) |

| MAX. PRESSURE DIFFERENCE IN FLOW DIRECTION | Polyacetal: 75 psid at 70 °F (5.2 bar at 21 °C) |

Resources

Brochures

- (PDF 964 KB, 5/31/2019)

- (PDF 952 KB, 5/31/2019)

- (PDF 967 KB, 5/31/2019)

- (PDF 1 MB, 5/31/2019)

Technical data sheets

- (PDF 708 KB, 5/2/2019)

- (PDF 698 KB, 5/2/2019)

- (PDF 700 KB, 5/2/2019)

- (PDF 670 KB, 5/2/2019)